Power fittings

Category: Power fittings

Product Details

Power hardware is a widely used metal accessory in power systems, mainly used to connect and combine various devices in power systems, playing a role in transmitting mechanical loads, electrical loads, and certain protection. The characteristics, applications, and classifications of power hardware are as follows:

Characteristics

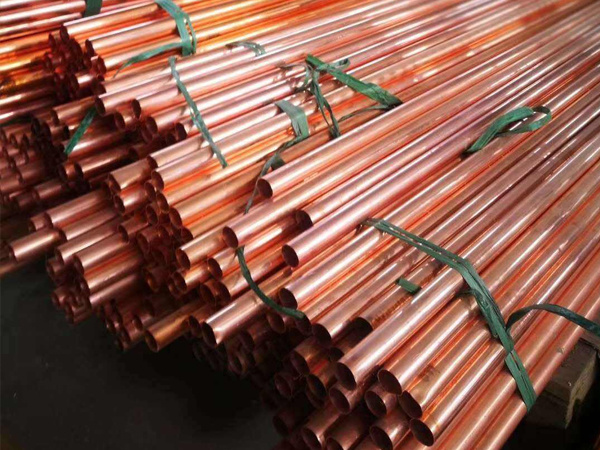

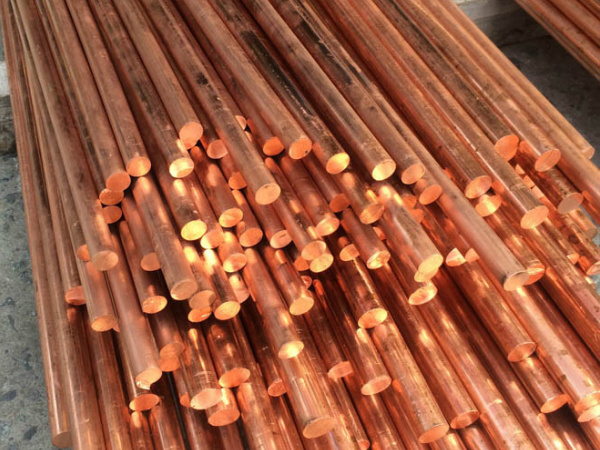

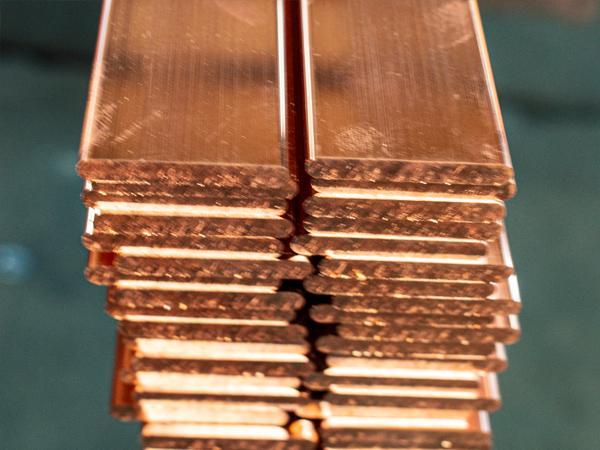

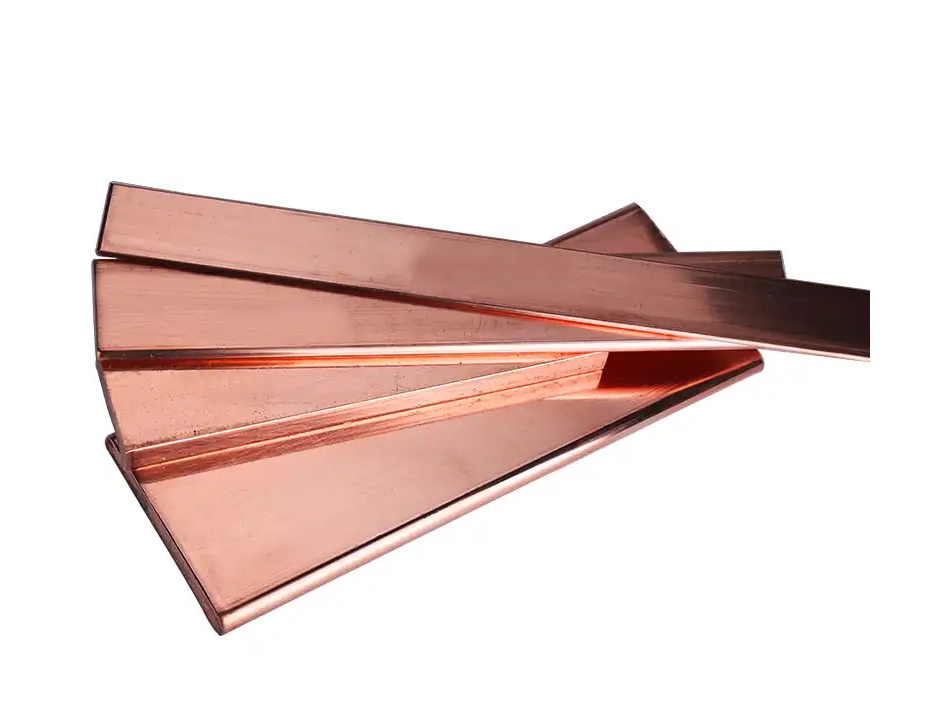

Various materials: Power hardware is usually made of iron, aluminum, or aluminum alloy, with good conductivity and mechanical strength.

Various functions: Power hardware is not only used to connect wires, cables, and other equipment, but also has various functions such as supporting, fixing, protecting, and insulating.

Widely used: Power hardware is widely used in power systems such as transmission lines, substations, and distribution devices to ensure stable transmission of current and stable operation of equipment.

Applications

Connecting function: Power hardware ensures stable current transmission by connecting wires, cables, and other equipment. They have the function of conducting current, fixing wires and cables, and reducing contact resistance.

Supporting function: Power hardware is used to support and fix wires, cables, and transformers, etc., to avoid mechanical damage, reduce vibration, and prevent swing.

Protective function: Power hardware can protect wires, cables, and transformers from external environmental influences, such as mechanical damage and corrosion.

Insulating function: Insulating hardware is used to transfer current from one conductor to another while isolating the two conductors to avoid short circuits or electric shocks.

Classification

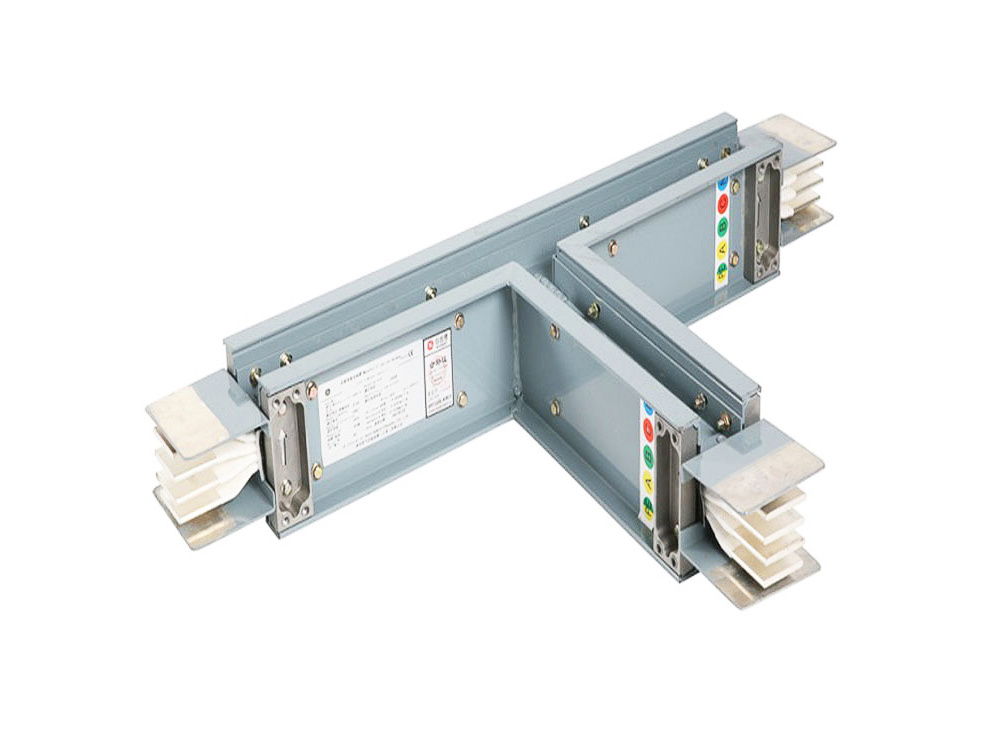

Connecting hardware: Mainly used in overhead power lines in power hardware construction and substations built by power bureaus, connecting wires or cables to other equipment or conductors, such as terminals, connectors, and cable heads.

Suspension clamps: Suitable for hanging conductor insulator strings on towers, and hanging jumpers on insulator strings.

Protective hardware: Used to protect other power hardware, reduce the vibration amplitude of overhead power lines and lightning protection wires, and has a uniform shielding effect, such as anti-vibration hammers and spacer rods.

Cable hardware: Such as DTL, DT, DL series copper-aluminum terminals, used for transition connections of various round, semi-circular, and fan-shaped aluminum wires, power cables, and copper ends of electrical equipment in distribution devices.

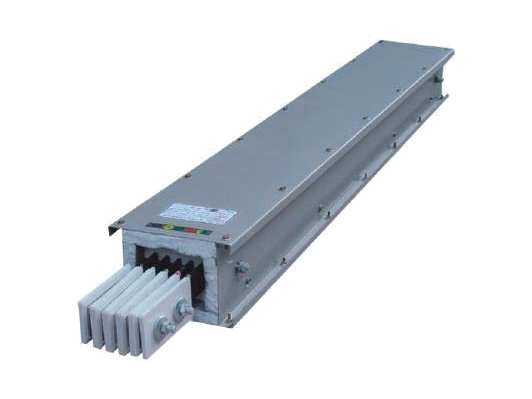

Equipment hardware: Mainly used for substation busbars, divided into aluminum stranded wires and steel-core aluminum stranded wires. Equipment clamps are divided into two types: copper transition equipment clamps and aluminum equipment clamps according to the material.

Continuous hardware: Used for the repair and continuity of overhead power lines and lightning protection wires. According to different installation methods and structures, they are divided into bolt type, pre-twisted wire type, and compression type.

Tension clamps: Used in overhead power lines and substations to fix conductors and lightning protection wires, connecting with connecting hardware and some tension insulators, or connecting lightning protection wires to towers.

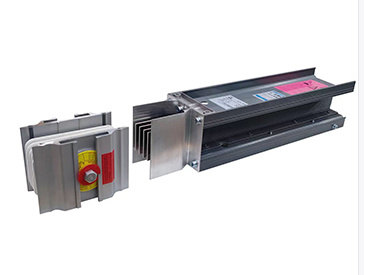

Power plant hardware: Also called current hardware, including hardware used in substations and power plants to support and fix soft conduits, multiple conductors, and various rigid busbars.

In summary, power hardware plays an important role in power systems. Its characteristics include diverse materials, diverse functions, and wide applications. The classification covers various specific types of hardware, each with its specific uses and functions.